01

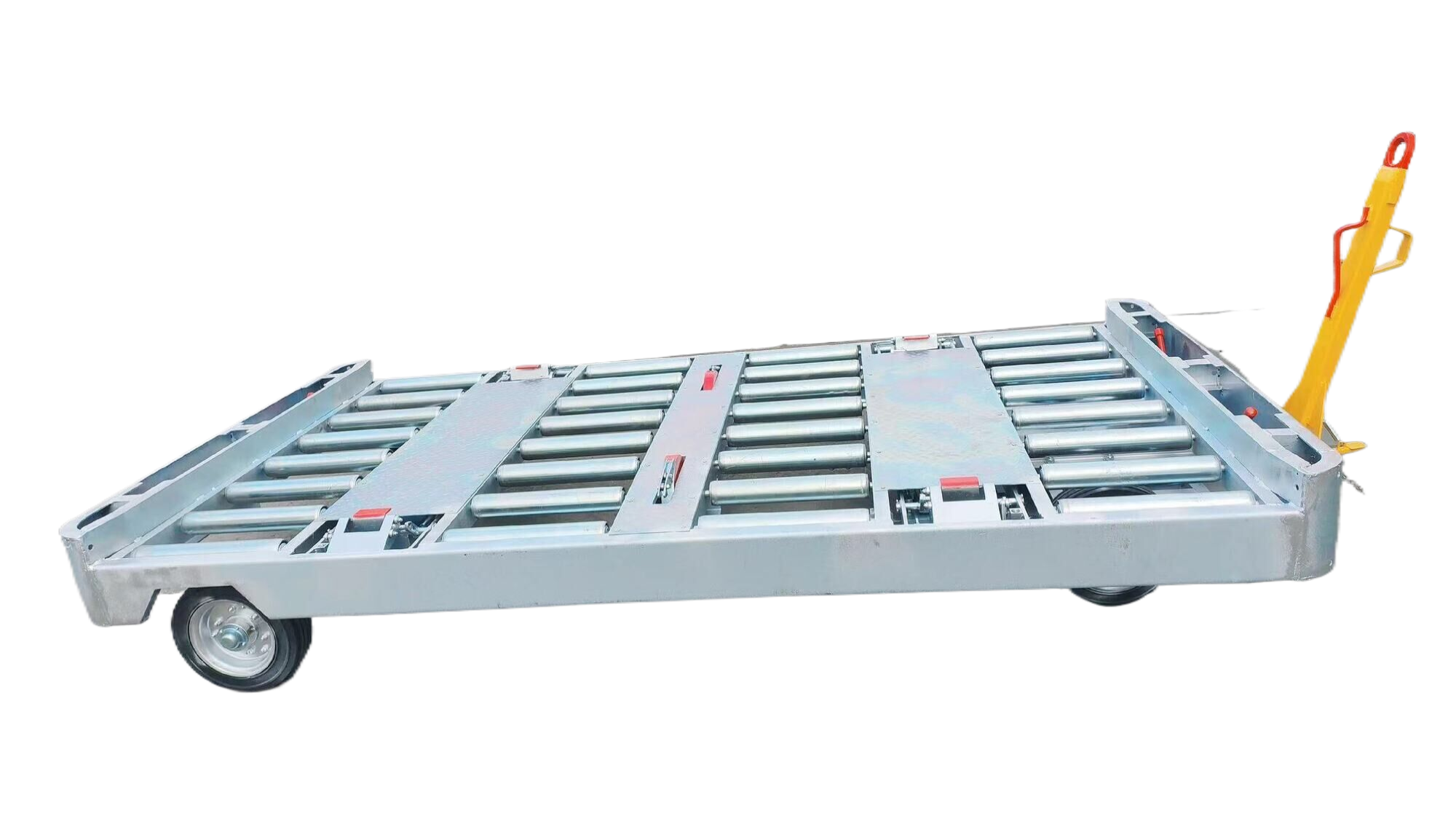

LD3 container dolly specification

Technical characterCHIDGE

1. The main frame of the trailer is welded by standard 8# channel steel. The welding is full welded and durable. The rotary platform of the trailer can be rotated at 360 degrees, and the 90 degree position is self stopping, and the operation is convenient.

2. The mop has multiple vehicle connections and droop after automatic braking, lifting the three functions of mop can also brake.

3. The car surface is made up of 22 galvanized drums which are 76 *5mm in diameter. The drums are flexible in rotation, light in transmission, wear-resistant and corrosion-resistant.

4. The tire adopts 15 x 4.5-8 rubber solid tire, which is wear-resistant and has a long service life.

5. The tail uses bayonet type drag hook, solid, insurance, operation is more convenient, interchangeability is strong.

6. The welding process of the vehicle is strictly in accordance with the welding standard of our company "welding operation instruction" to ensure the strength requirements of the main frame.

7. According to the size of the container, the car surface is equipped with movable limit turning plate, both sides are equipped with fixed limit guiding wheels and baffles, so that the container does not move or derail during the loading process.

8. This trailer is suitable for loading LD1, LD2 and LD3 containers. The platform has flexible rotation and small turning radius.

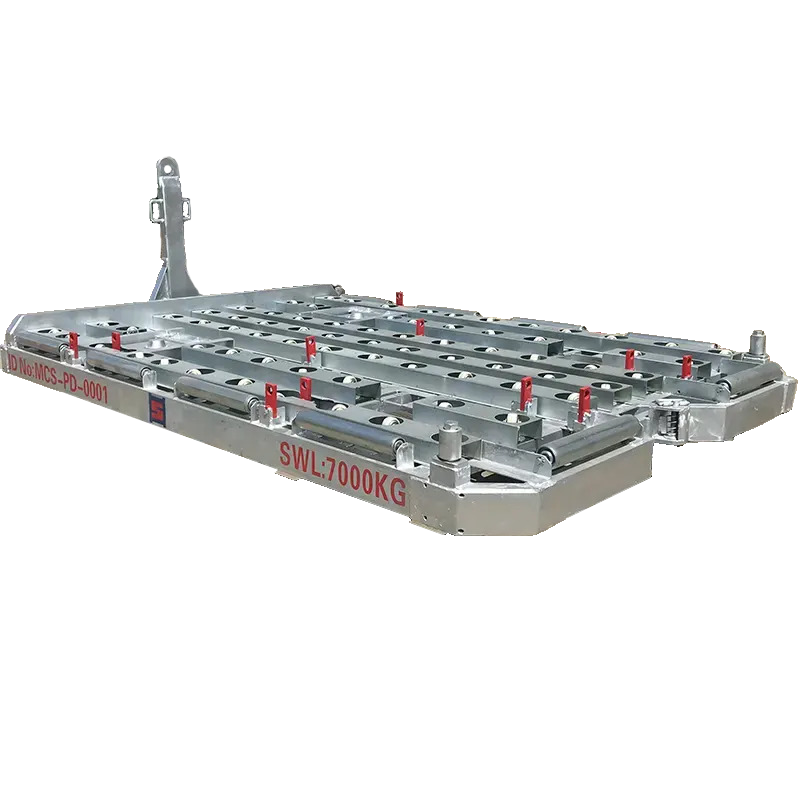

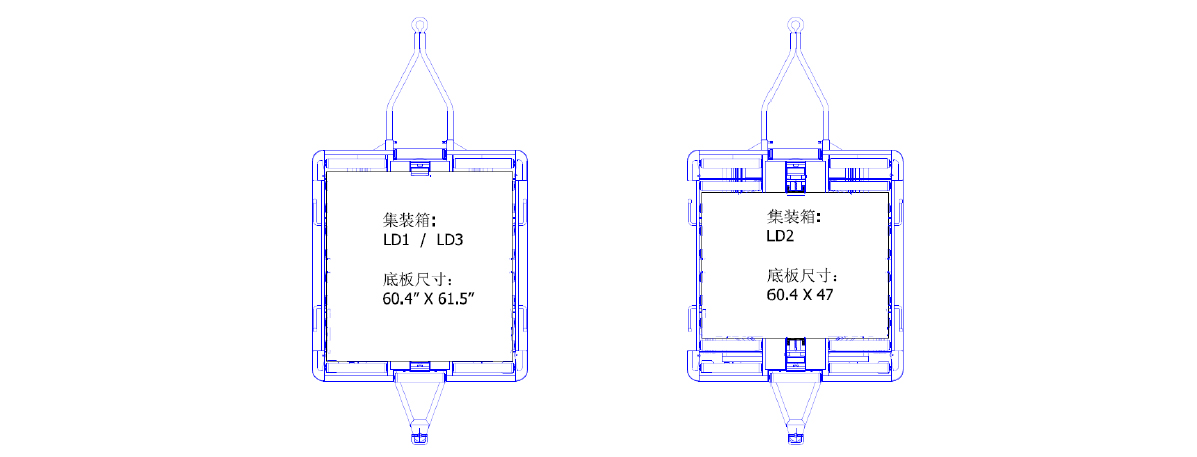

Suitable loading

LD1 60.4"*61.5"×1

LD2 60.4"*47" ×1

LD3 60.4"*61.5"×1

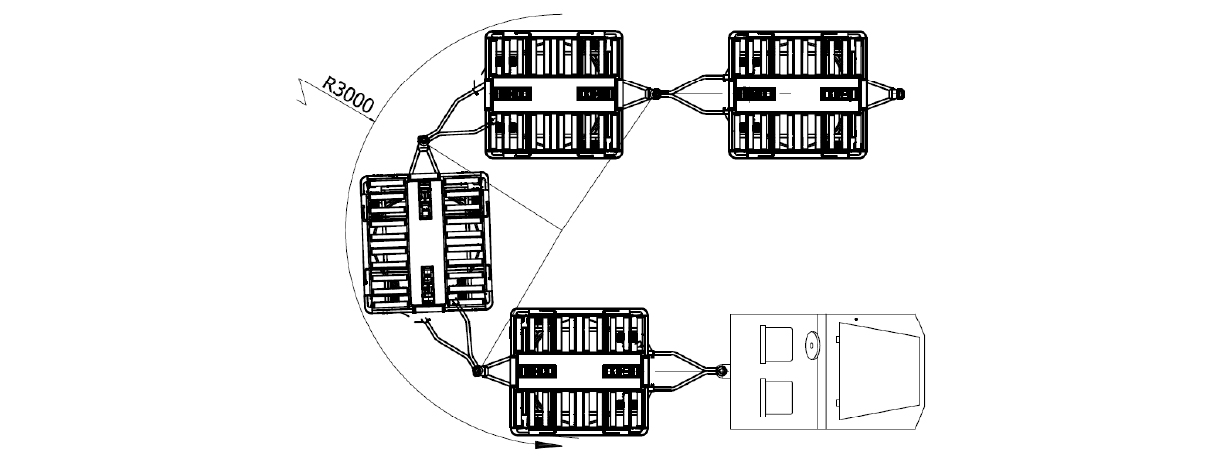

2. Turning radius≤3000mm

The trailer turning radius as follows drawing.

Technical parameterCHIDGE

| Whole height | 560mm |

| Platform height | 508-518mm |

| Loading weight | ≥2000kg |

| Speed | ≥25km/h |

| Weight | ≥600kg |

| Min turning radius | ≤3000mm |

| Size | 3616mm*1760mm*560mm |

| Platform size | 1900mm*1760mm*518mm |

chassis introductionCHIDGE

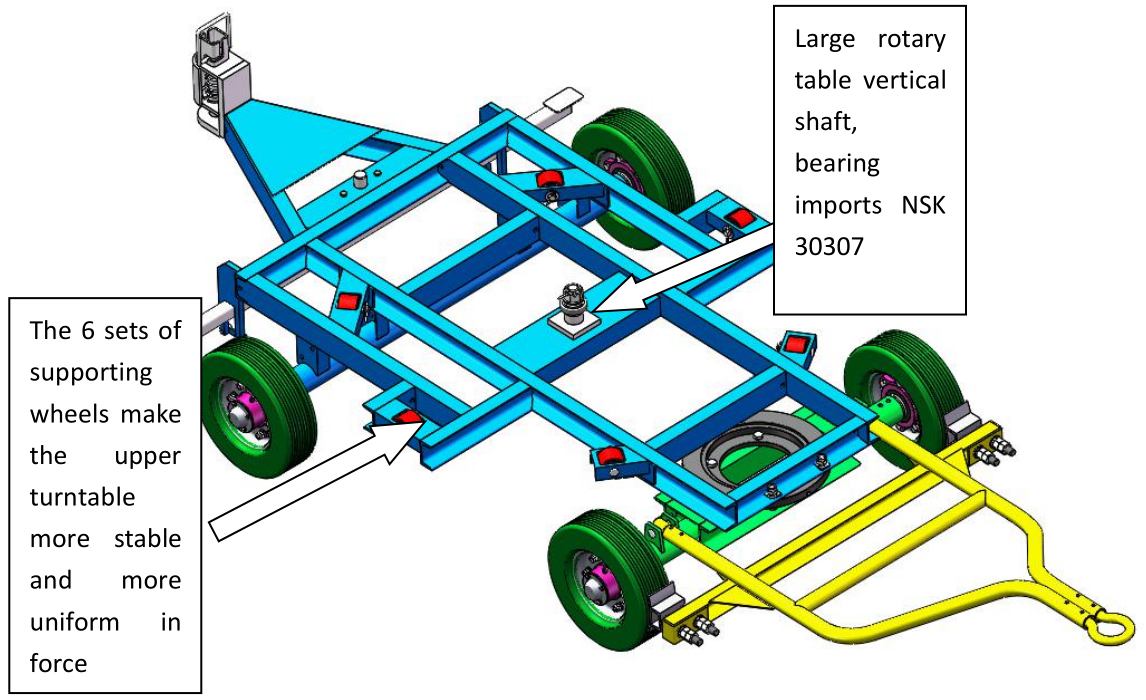

1. The chassis is welded by standard 8# channel steel and full welding is used.

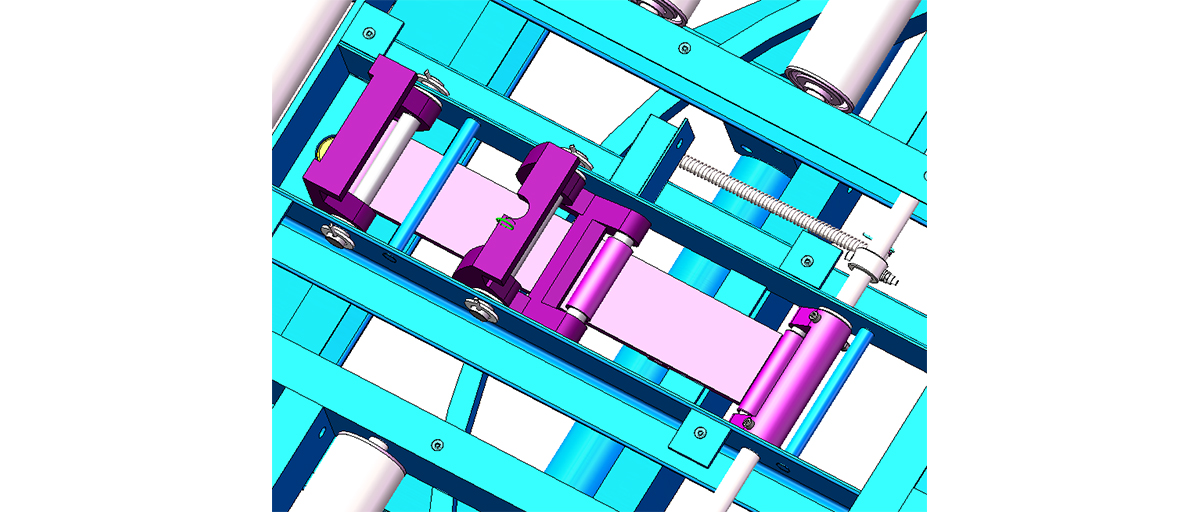

2. The frame is equipped with a special turntable structure. It is composed of six guide wheels, rotating rings, central axes, central bearing blocks and bearings.

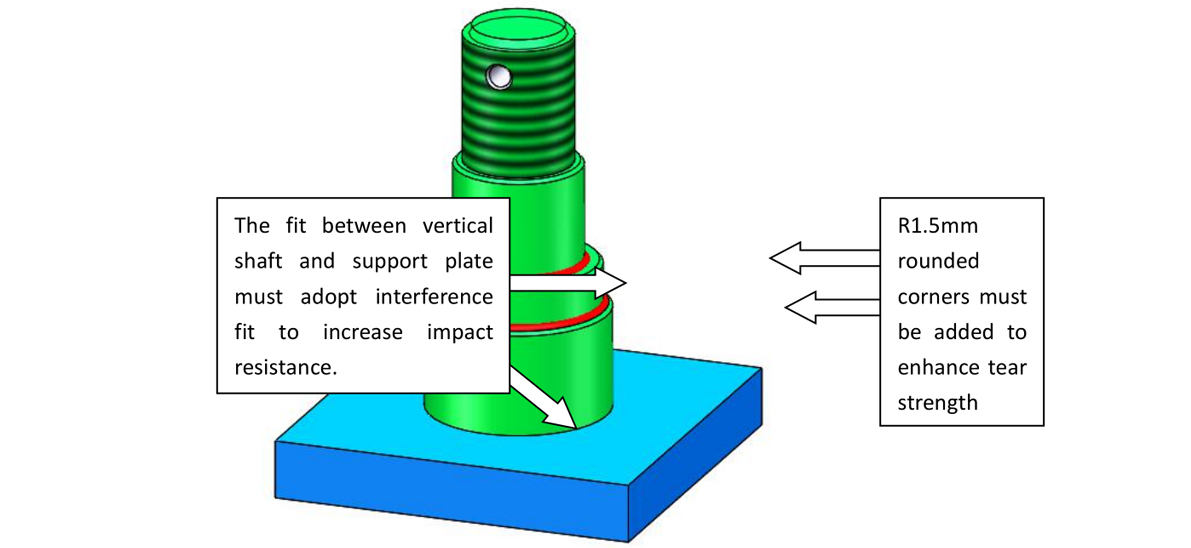

Introduction of rotating platform structureCHIDGE

The rotating platform takes the center shaft as the rotating shaft and makes the rotation more flexible. The stability and firmness of the supporting frame are determined by six guide wheels. The center shaft is made of high quality 40Cr steel. After quenching and tempering heat treatment, the service life of the whole vehicle can be fully guaranteed.

1. Bearing type: 6207.

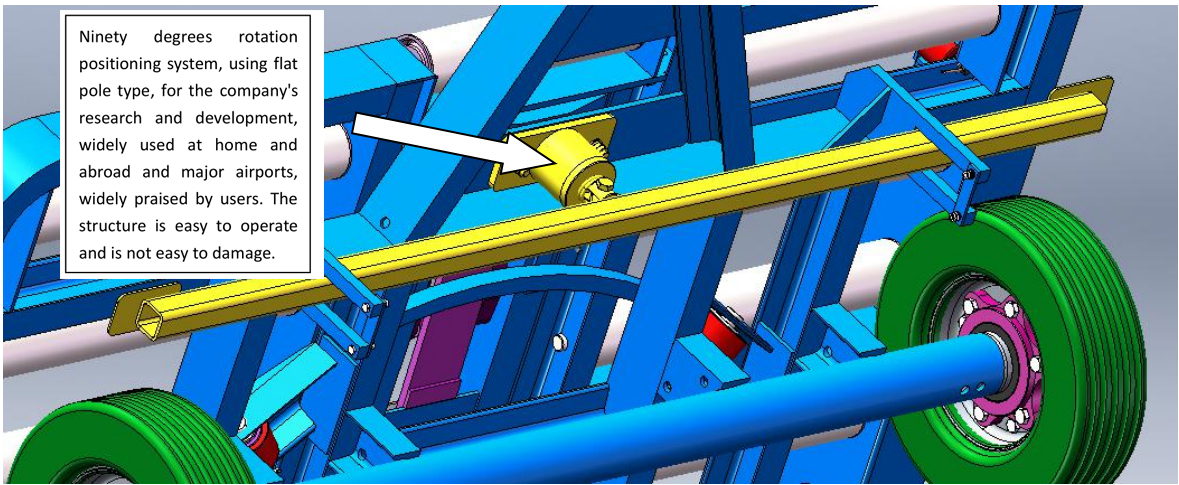

2. The rotation angle is 360 degrees, and the self stop limit is 90 degrees.

3. The frame structure is composed of six supporting wheels, rotating rings, central axes, central bearing blocks and bearings.

4. 2 guide wheels are installed at the edges of both sides of the upper frame to assist.

5. Specifications and materials: 8 channel steel, 10# flat steel, 5mm steel plate, material Q235A.

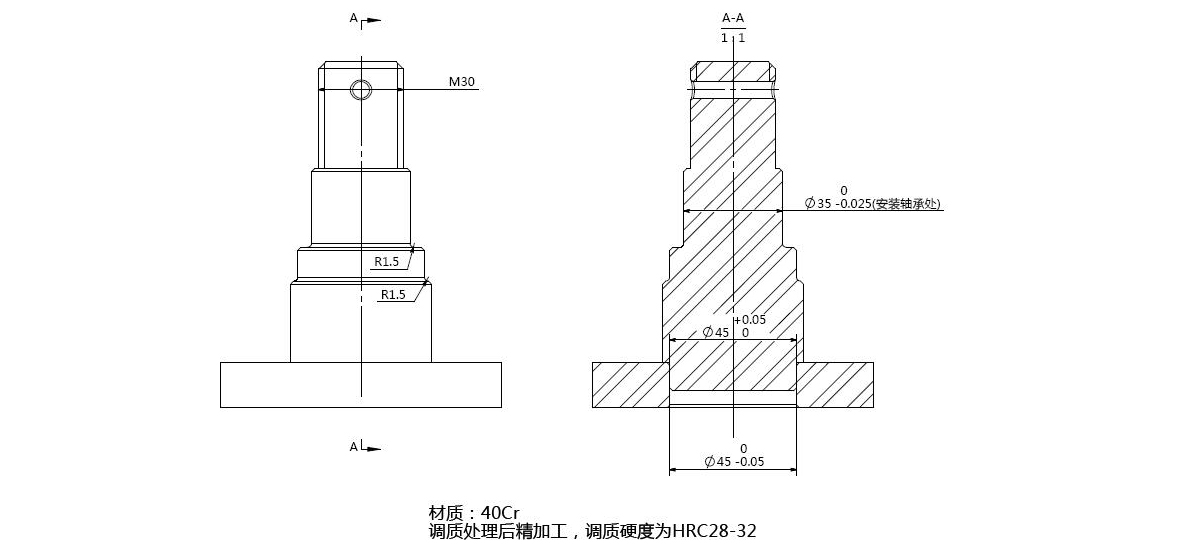

center vertical axisCHIDGE

1. The center vertical shaft is heat treated and tempered with 40Cr round steel after rough turning (hardness HBC28-32), which improves the internal molecular structure of the vertical shaft and makes it obtain excellent comprehensive mechanical properties and impact toughness.

2. After finishing, and at the same time, we should have R1.5 fillet at every step angle to enhance tear strength.

3. Installation of bearings should be carried out with the gap between bearings to facilitate installation.

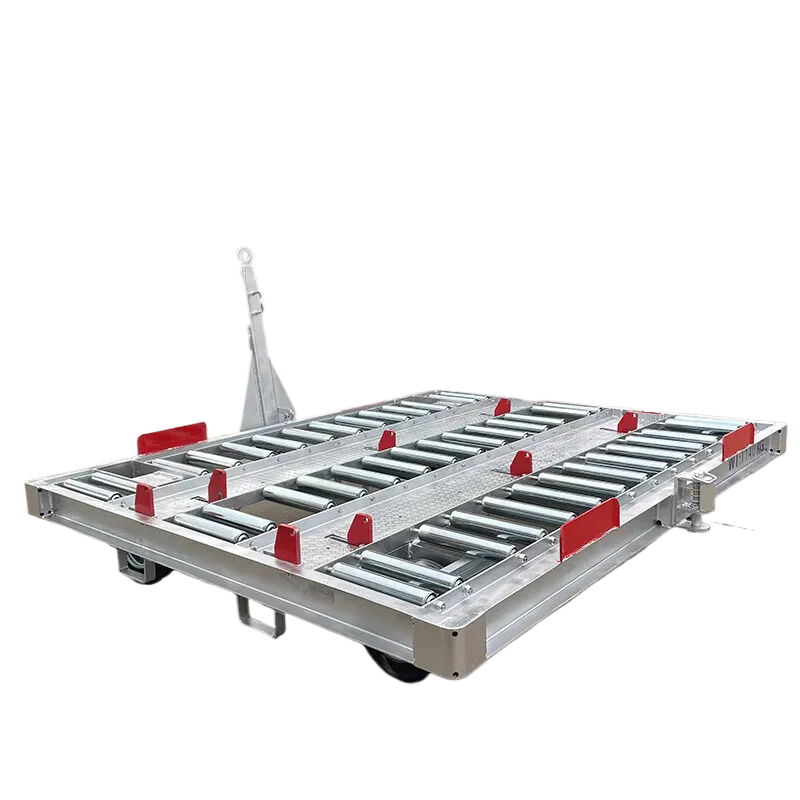

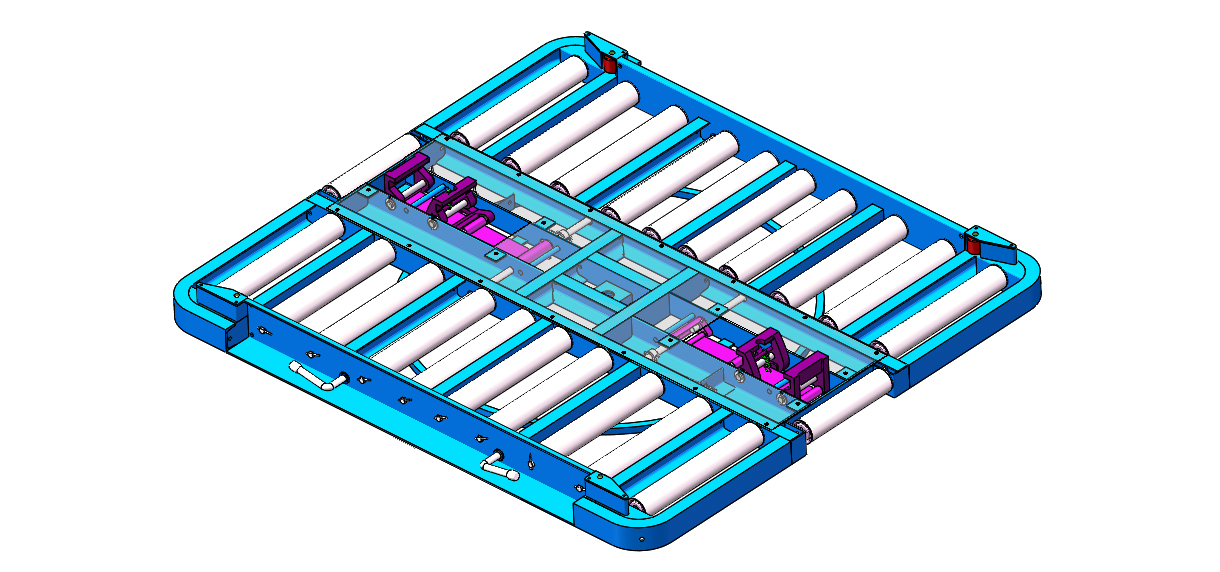

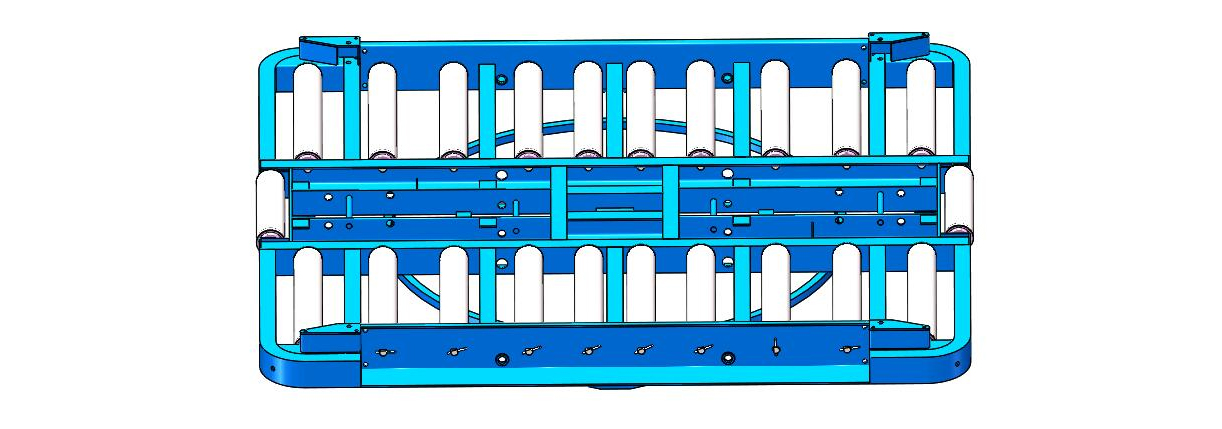

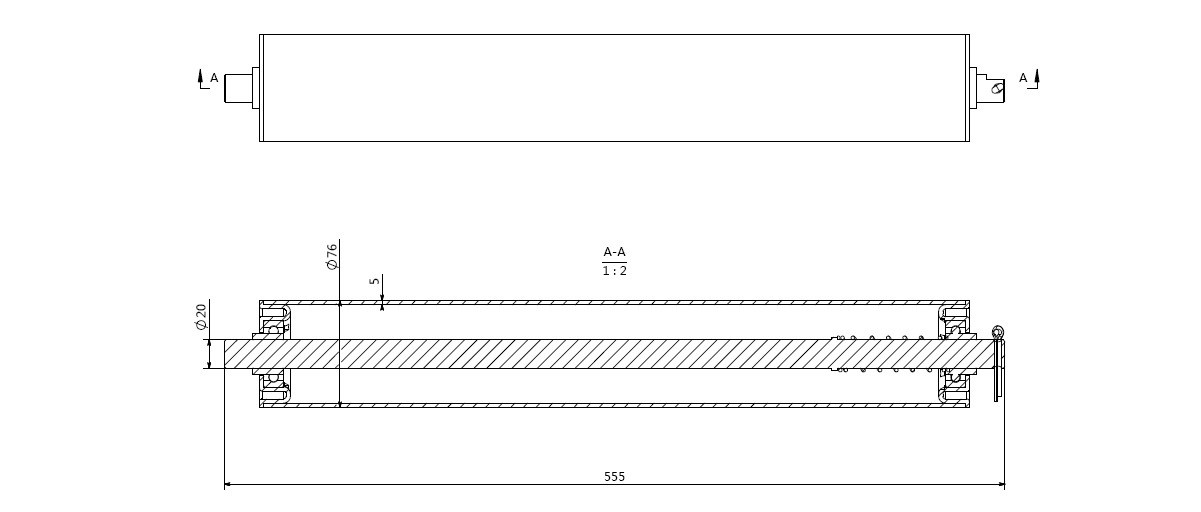

Roller mechanismCHIDGE

1. The drum rack adopts 8# channel steel and 5mm steel plate.

2. The roller pipe is made of seamless steel pipe with a diameter of 76 x 5mm (Galvanized).

3. The total length of the roller shaft is 555mm, the roller shaft adopts the 20mm round steel and the 10 rollers on both sides of the turntable.

4. The total length of the two short drums in the middle of the left and right ends of the box towing table is 395 mm. The drum shaft is made of_20mm round steel.

5. One end of the roller shaft is opened with a semi circle, installed on the 5mm steel plate, and the other end of the roller is installed on the channel steel.

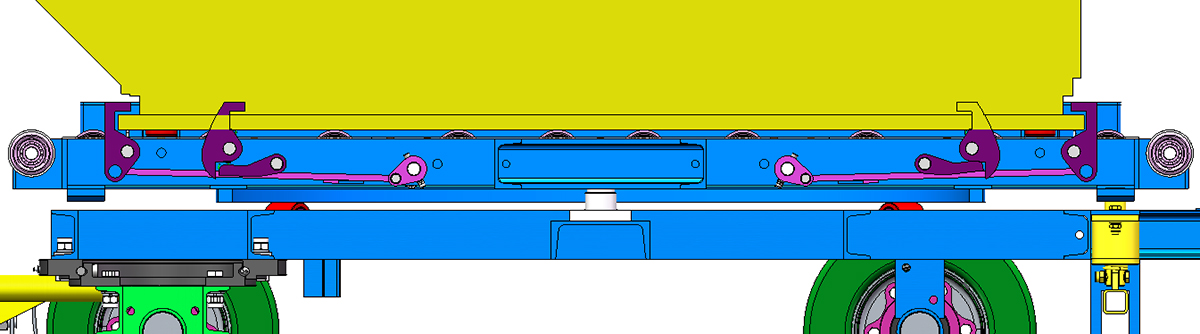

box lock mechanismCHIDGE

1. Cast steel is made of cast steel, durable and durable.

2. The turning plate is connected with the transmission handle, which can be turned over according to the actual use, and can hold the container within the limit to prevent the container from jumping during the movement.

3. The turning plate adopts double locking structure. The distance between the turning plates is designed to be 1570mm, 1200mm and two specifications. It can be used for loading LD3, LD2 and LD1 aviation containers.

4. Make a pair of locks on the left and right sides of the container. The locks (45# cast steel sheets) must fasten the bottom edges of the container.

5. The baffle mechanism composed of four hook-shaped baffles on the right and two fixed baffles on both sides of the trailer can effectively restrain the bottom plates of LD1, LD2 and LD3, and ensure that the container does not jump or drop during the loading process.

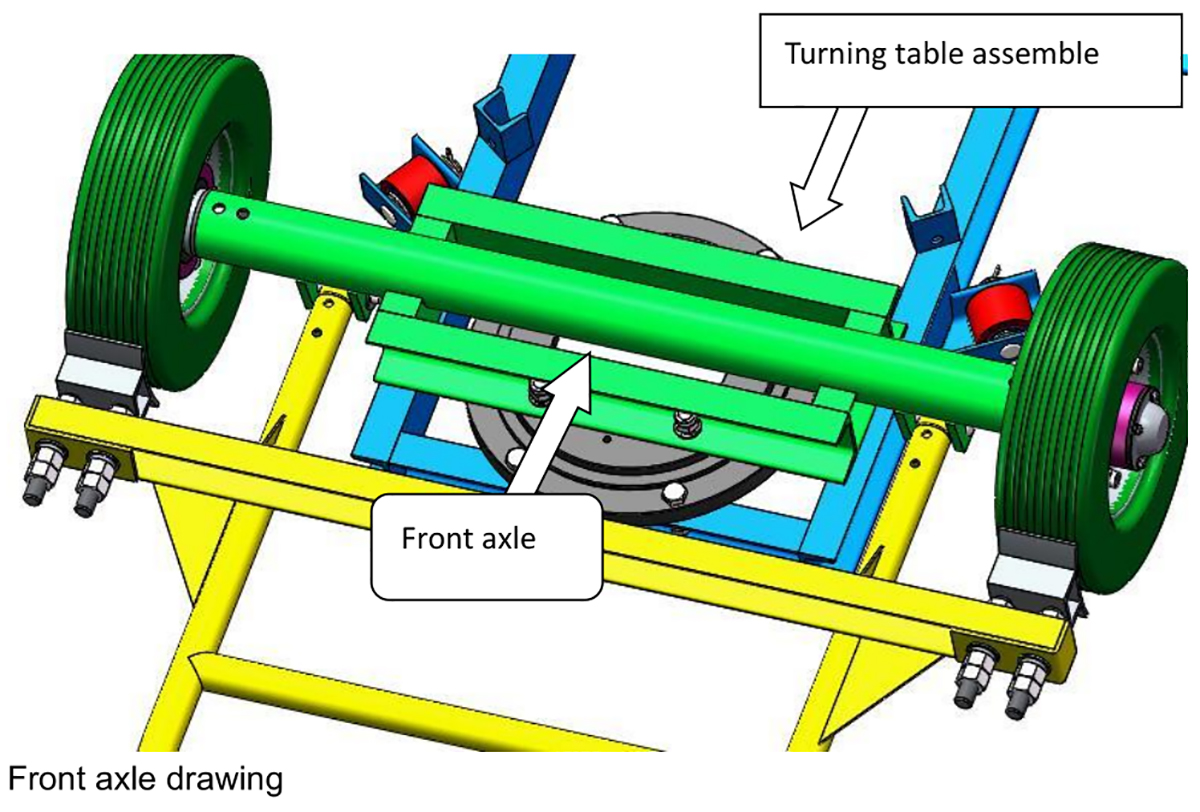

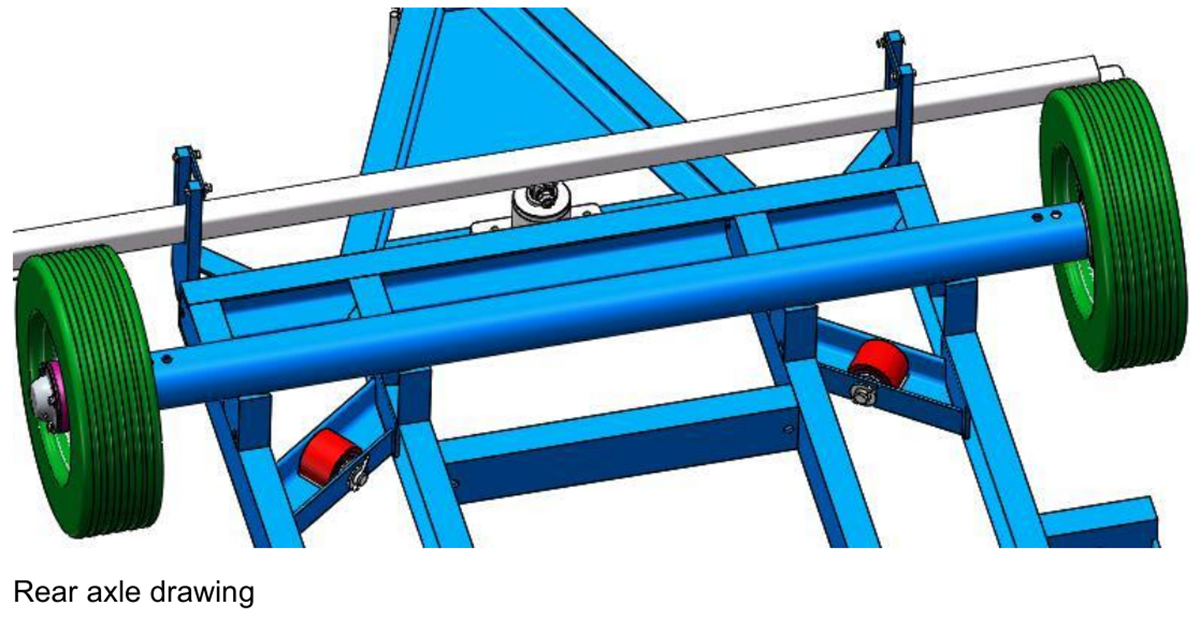

Front and rear axle mechanismCHIDGE

1. Specification and material: 76 * 5 seamless steel tube.

2. The front axle and the frame are fixed through the turntable.

3. The rear axle and the frame are fixed by 8# channel steel.

4. The connection between the front axle head and the seamless steel pipe is perforated and full welded.

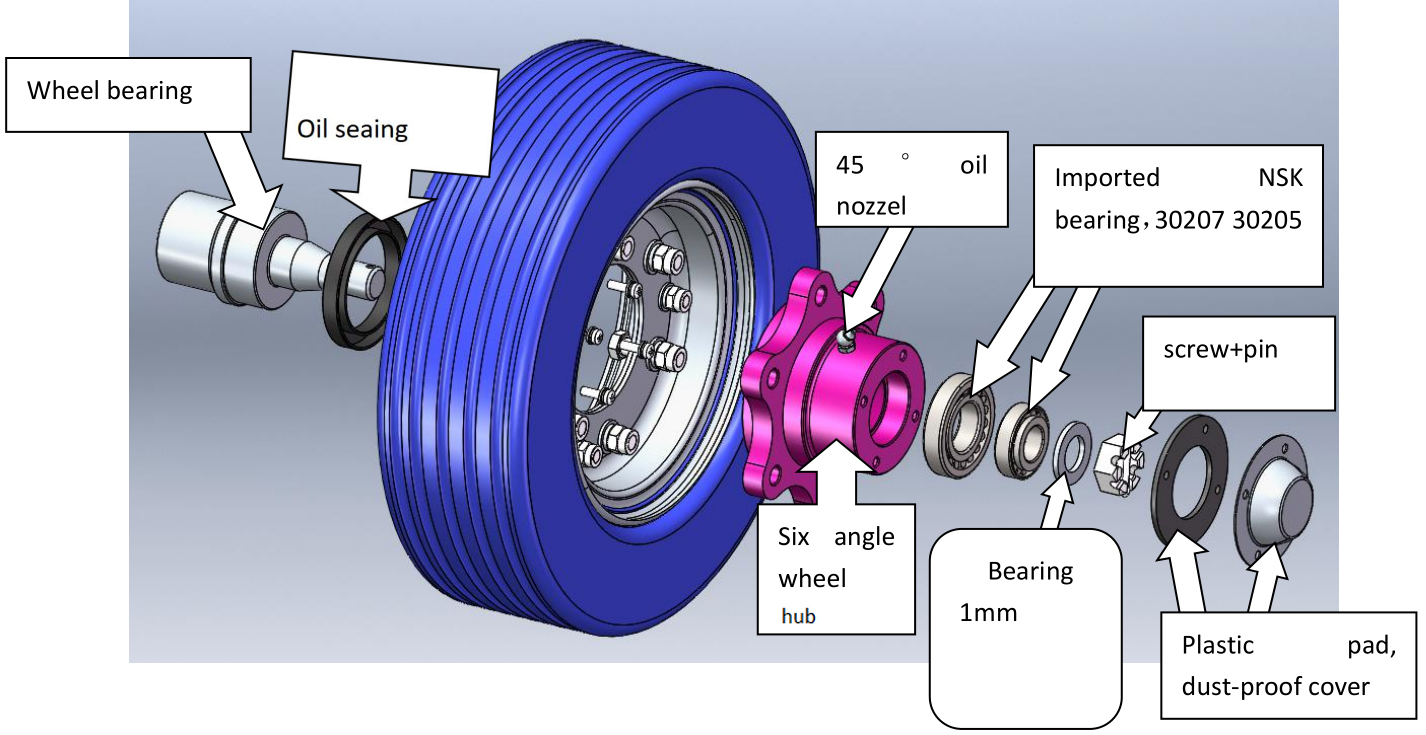

wheels and tyresCHIDGE

1. Hub diameter is 290mm, middle flange seat hole diameter 100mm, ring fastening screw 10mm, tire screw hole 14mm. The tire is made of 15X4.5-8 solid tire produced by Shanghai Jiuda Company. The tire is made of imported rubber, which is more wear-resistant in use (the attachment contains the import declaration form of rubber and the test report of the tire).

2. Bearings are imported NSK, models are 30207 and 30205. Butter nozzles are added to the hub to facilitate lubricating oil filling. Great Wall brand is used as lubricating grease. The temperature of lubricating grease is - 20-120%. (attached first inspection report)

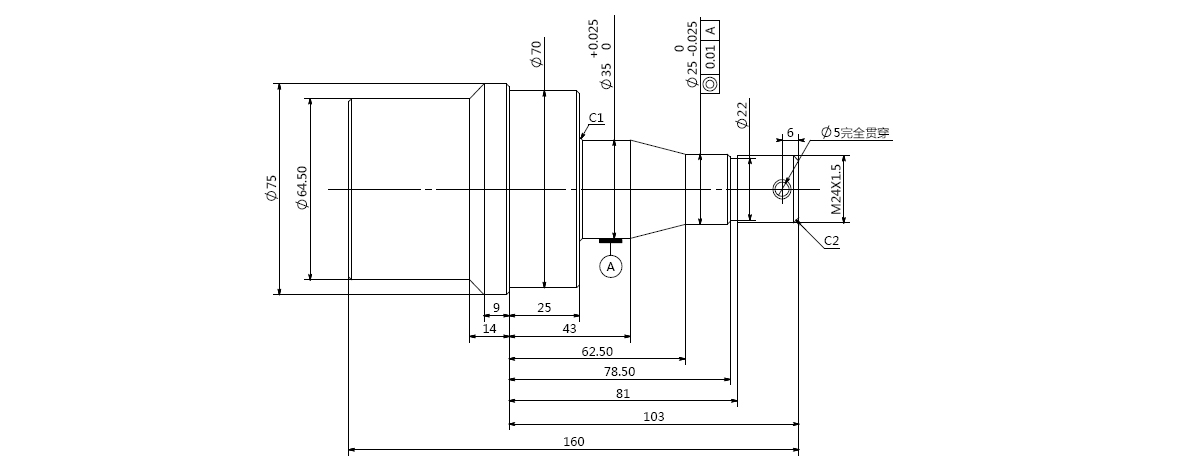

4. The tire shaft head is tempered and processed with 40Cr steel. The size of 30207 bearing must be clearance fit for easy installation. The size of 30205 bearing must be interference fit for strengthening strength. At the same time, the strength of the bearing must be chamfered to strengthen the strength of the shaft head.

drawbar and brake structureCHIDGE

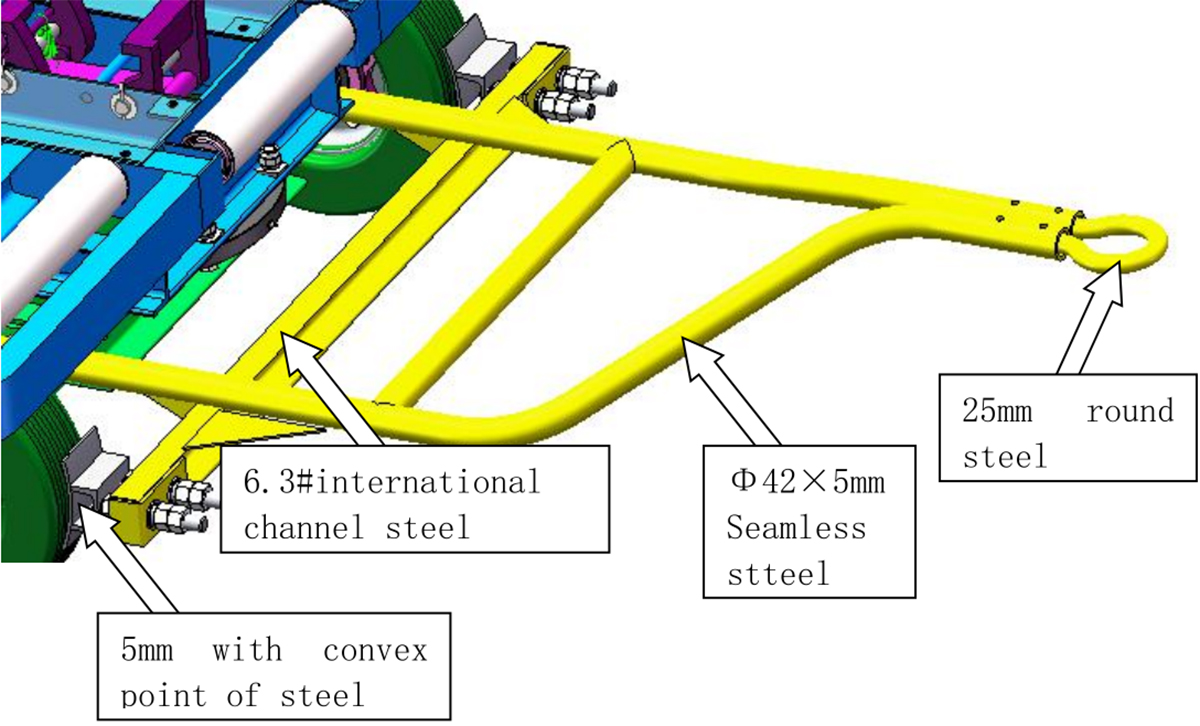

1. Drawbar length 1300mm, width 800mm.

2. The distance between the end of the mop end and the front bridge is 25mm and the aperture is 21mm.

3. The drawbar is made of 42 *5mm seamless steel pipe, the pulling ring of the mop head is made of 25 round steel, the mop head is inserted into the seamless steel pipe part of 70mm, the insertion part is fully welded with pins, and the inner diameter of the mop hole is 75mm.

4. The height difference between the middle line of the mop head and the middle line of the drawbar tail is 180mm.

5. A 150 mm x 150 mm triangular steel plate is welded at the joint of the drawbar and the brake crossbar, and the thickness of the steel plate is 6 mm.

6, the external front wheel brakes: the use of drawbar's gravity droop to connect the device to produce braking effect. Under the brake condition, the bottom edge of the mop head is off the ground 70-150mm.

7. The length of the brake cross bar is the same as that of the front wheel alignment. 6.3# national standard channel steel is used.

8. The brake part is made of arc shaped surface with raised steel plates, the thickness of the steel plate is 5mm, and the length is 160mm.

9. The brake shall adopt two adjustable wheels. The adjustable brake shall adopt internal and external double nuts. The external side shall be self-locking nuts. All nuts shall be fitted with spring gaskets.

hook requirements: the use of bayonet hook

CHIDGE

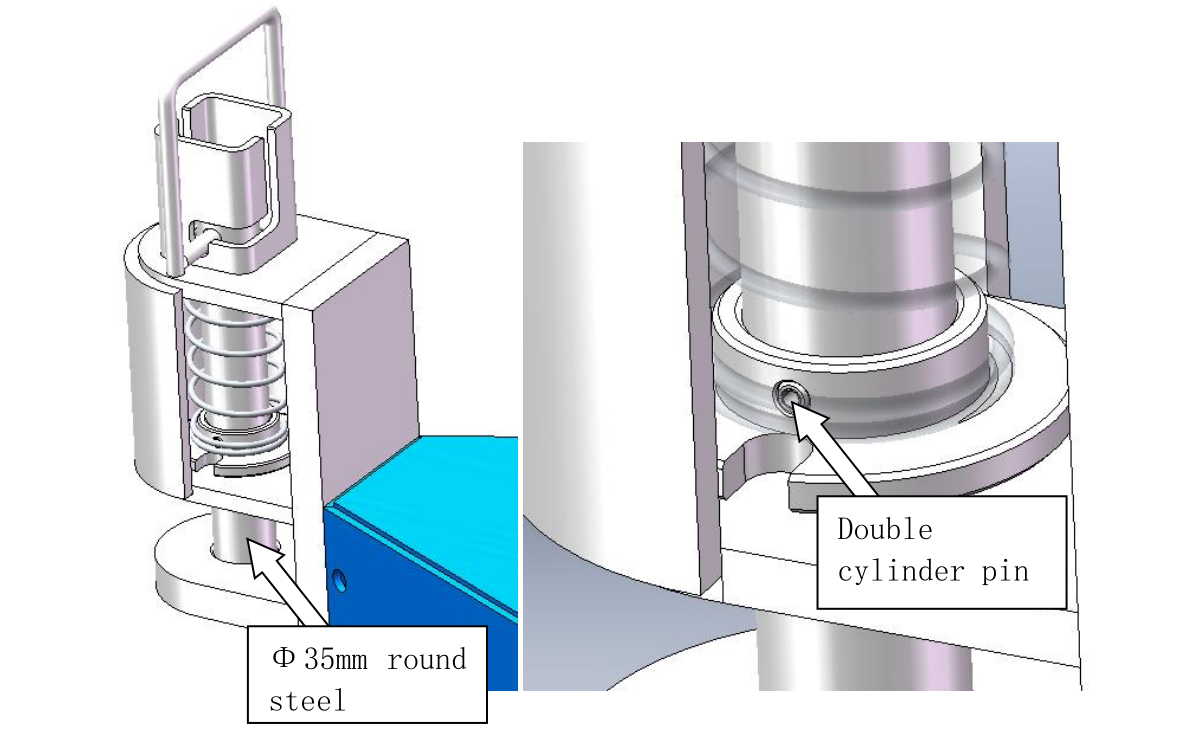

1. The length of the hook is 280 mm, the width is 100 mm, the specification of the pulling ring is 120 mm *120 mm, made of_10 round steel, and the height of the tail hook sleeve is 75 mm.

2. The total length of tail hook core is 230 mm, diameter is 35mm, 45 # steel is used to polish round steel, quenched and tempered and galvanized, and the bottom is 20 mm steel plate to ensure high strength.

3. The height of the tail hook seat is 300mm, and the distance between the bolt hole and the tail hook fixing plate is 65mm.

4. When the mop and the hook need to be separated, the operator only needs to pull the handle to rotate the shaft pin to the lifting opening of the shield. Lift the bolt, and the mop is easily separated from the hook.

5. The double elastic cylinder pin is used to fix the gasket to ensure that no accidents such as pin skipping occur during the running of the vehicle.

Surface treatmentCHIDGE

The car is made of sandblasting, grinding, hot dip galvanizing and rust proof treatment to ensure that the vehicles are bright and clean without rust.

Products

Products