01

CD-BL80 self-propelled conveyor belt loader

Equipment StandardCHIDGE

➢ IATA AHM 905 Reference Material of Civil Airport Terminals.

➢ IATA AHM 910 Basic Requirement of Airport Ground Support Equipment.

➢ IATA AHM 913 Basic Safety Requirement of Airport Ground Support Equipment.

➢ IATA AHM-925 Technical Requirement of Self-propelled Conveyor Belt Loader.

➢ MH/T 6030-2014 Bulk Cargo and Luggage Belt Loader.

➢ AC-137-CA-2015-17 Testing Regulation of Self-propelled Conveyor Belt Loader.

Work ConditionCHIDGE

Altitude: ≤3000 m

Ambient Temperature: -40℃ ~+65℃

Technical ParametersCHIDGE

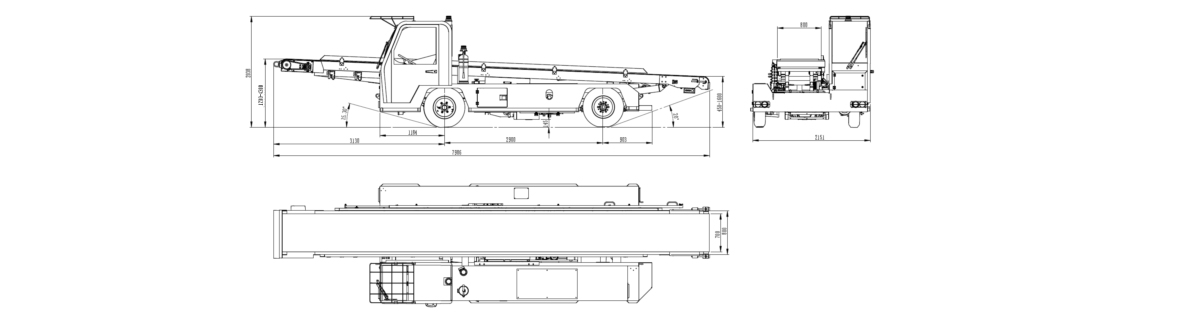

| Overall Dimension | 8000×2100×1650 mm |

| Min. Turning Radius | 6500mm |

| Wheel base | 2900mm |

| Front Wheel tread | 1725mm |

| Rear Wheel tread | 1695mm |

| Max Grade ability (°) | 30 |

| Ground Clearance | 145 mm |

| Shipping Weight | 3200 kg |

| Belt Width | 700 mm |

| Boom Length | 8000 mm |

| Conveying speed | 0.2-0.5 m/s |

| Max distribution load of conveyor belt | 135 Kg/m |

| Work height range of front end | 1200-4300 mm |

| Height range of rear conveyor end | 1600-450mm |

| Max Inclination angle | 29° |

Main Structure and ConfigurationCHIDGE

➢ Power and Transmission System

CUMMINS DIESEL ENGINE

Engine Model: QSF2.8t3Na49

Type: Four cylinders, Four strokes, Water coolant, Straight line, EU Stage IIIA emission standard

Displacement: 2.8L

Max Output capacity: 49hp (36kw) / 2500 rpm

Max output torque:186Nm / 1100-1500rpm

The engine is equipped with USA original Horton fan with famous brand large capacity aluminum fin type radiator, large capacity water filling tank and large capacity air filter.

OKAMURA AUTOMATIC TRANSMISSION

Model: Y43280D, Japanese Origin

Type: Hydraulic automatic transmission, single stage torque converter, 2 Phase, 3 components comprehensive type, simple structure and stable performance.

Front one gear, Rear one gear

➢ Tractor Axles, Tires, Brake system

1. Front Axle:

Type: Steering axle with hydraulic disc brake, single-side double-clamp twin cylinder brake, with pay load of 3ton.

Option: Front axle with steel plate spring absorber system

2. Rear Axle

Type: Driving axle with drum type walking brake and parking brake, with 3Ton pay load.

3. Wheel

Type: Radial type, Steel Wiring Tire, 7.00R15

(Tubeless tires are available upon request)

4. Brake system

8 + 9 Inch Vacuum Power assisted system

➢ Electric System

12V DC Electric system, negative grounded

80Ah Maintenance Free Battery, LED Light for Complete vehicle including Head light, CAN Wiring device, High qualified vehicle gear shifter, Germany original Weidmuller Relays.

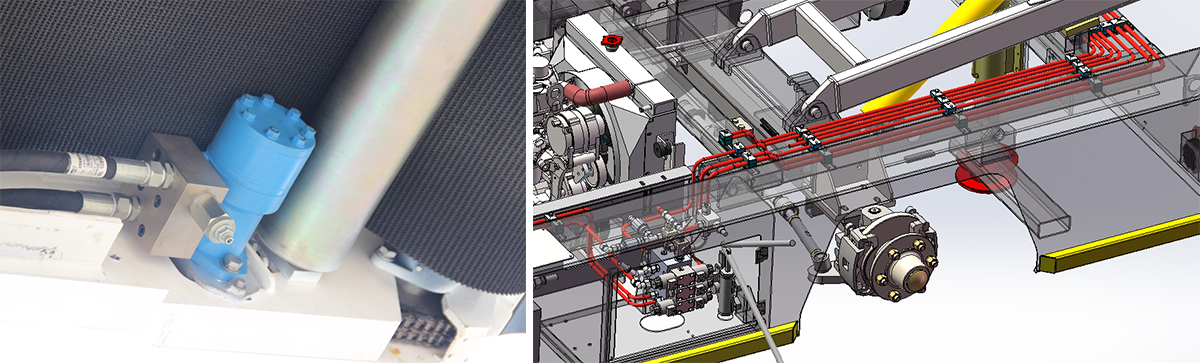

➢ Hydraulic System

The hydraulic system consists of main configurations as below:

1. 90L Hydraulic Tank.

2. Chinese best branded Hydraulic pump.

3. Italian branded HV hand pump.

4. EATON hydraulic valve sets, Italian OM Piping valves, best Chinese Card connector and hydraulic pipe as well as Parker soft hydraulic pipes.

The hydraulic system is available with the emergency retrievable stabilizer and the emergency lifting & lowering function for both front and rear lift frame. The complete piping design is hard type so that it keeps the same long time as the vehicle operation.

Hydraulic components and layout diagram

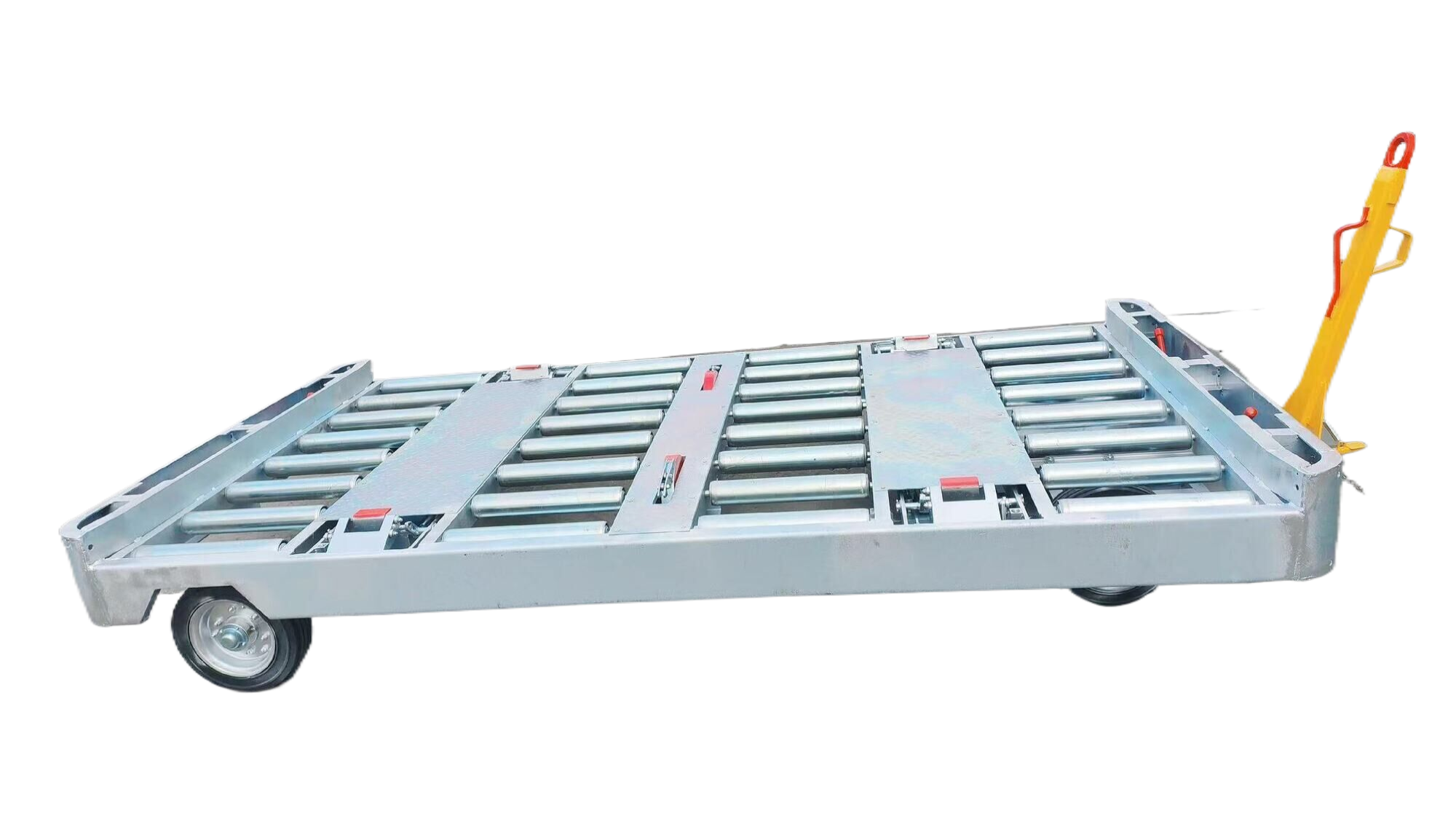

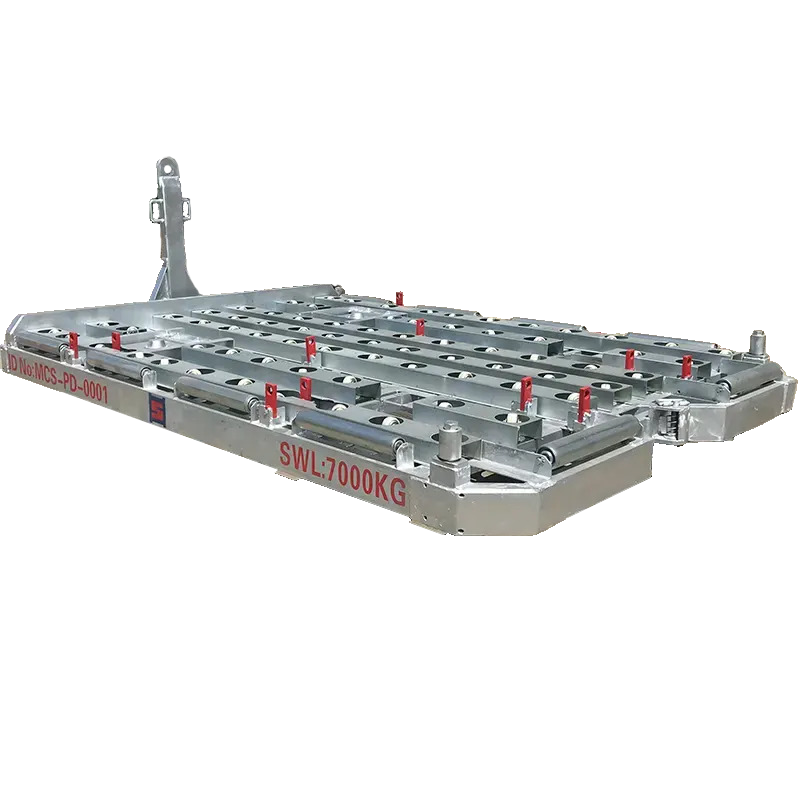

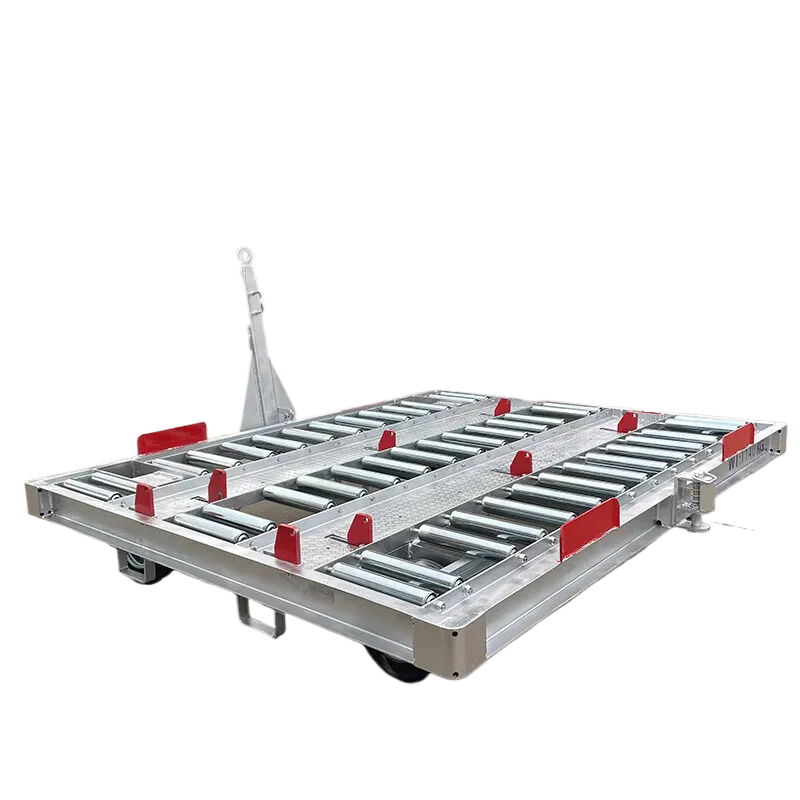

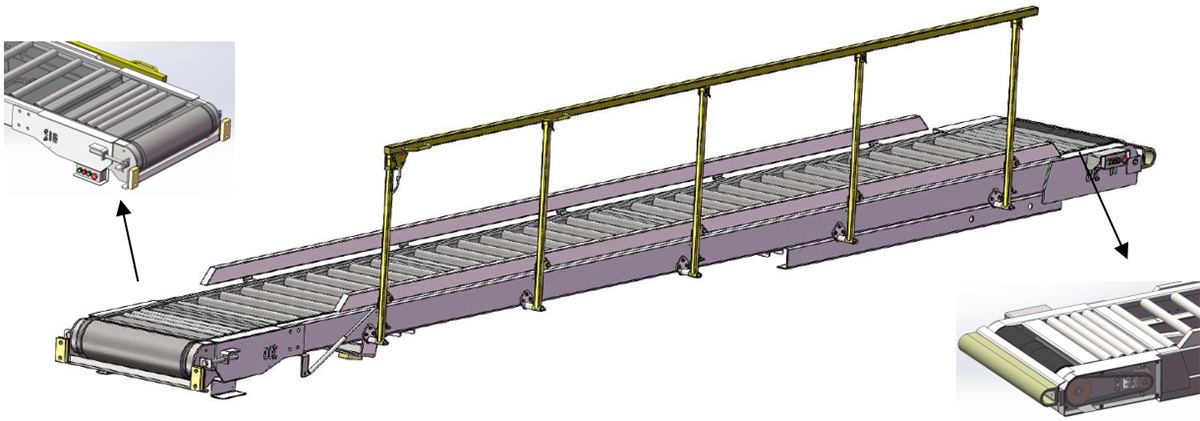

➢ Conveyor Frame Part

The conveyor frame consists of main frame in width of 800mm, heavy loaded type rollers, drive rollers, driven rollers, adjusting rollers, drive motors, etc.

1. The front drive roller is PU rubber packed in diameter of 210mm, which provides adequate friction and have long service life.

2. The rear end is belt tension assembly with 160mm adjusting range for forward and back, which makes the conveyor belt easily disassembled and maintained.

3. The load rollers are in thickness of 2mm. The distance between both front and rear ends are 700mm which can prevent luggage not being crashed during transportation. The middle distance is 180mm which makes it is easily for maintenance.

4. The belt width is 700mm in thickness 8mm three-layer type that is famous Taiwan NANG brand. There’re two sets of conveyor deviation correcting devices installed at lower end so as to ensure it running in right track without any deviation.

5. Front hydraulic motor as driving system can provide maximum conveying power. It can transport maximum 1200KG cargo or luggage.

6. There are stainless guiding baffles at two sides of the conveyor frame so as to prevent luggage dropping off. The right side baffle can be foldable together with the handrails. The handrail height lifted is 850mm or it could be 1000mm as required.

Conveyor frame illustration diagram

➢ Options

Water proof Canopy on conveyor.

Without Driver's cab.

Cool/Heat Air Conditioner.

Heater in driver's cab.

Reversing Visual Image system.

Front Stabilizer.

Lamp Cover.

Both Left and right rubber bumper.

Painting Color per requirement.

➢ Shipping Documents

Operation Manual of CT-BL80 self-propelled conveyor belt loader.

Spare Parts book of the belt loader.

Cummins QSF2.8 Diesel Engine manual.

Okamura Y4328D Transmission manual.

Quality Certificate of the vehicle.

Software including documents as required.

Products

Products